Accessible at all times, 24/7, delivering uninterrupted support.

Baling Press

24/7 Clients Support

Creative Ideas

Emphasizes your innovative approach to problem-solving.

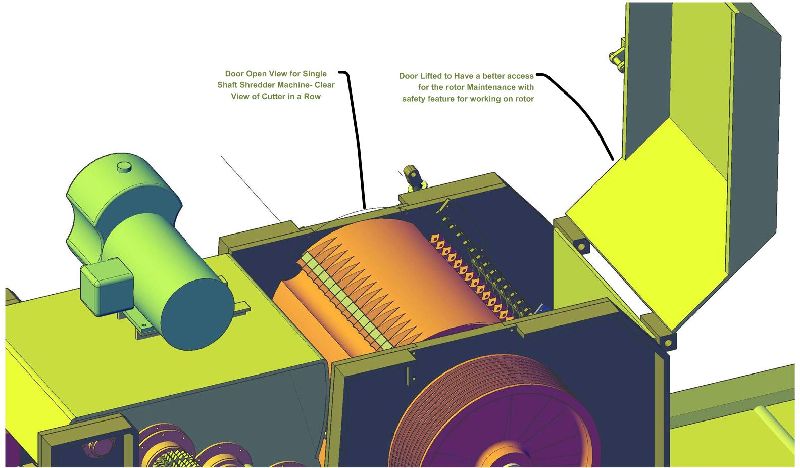

Super Safety

Positions safety as a top priority and differentiator.